Umvelisi oThengisa ngokuNgqo ngokuBusulungekileyo obuPhezulu

Ingcaciso yeMveliso

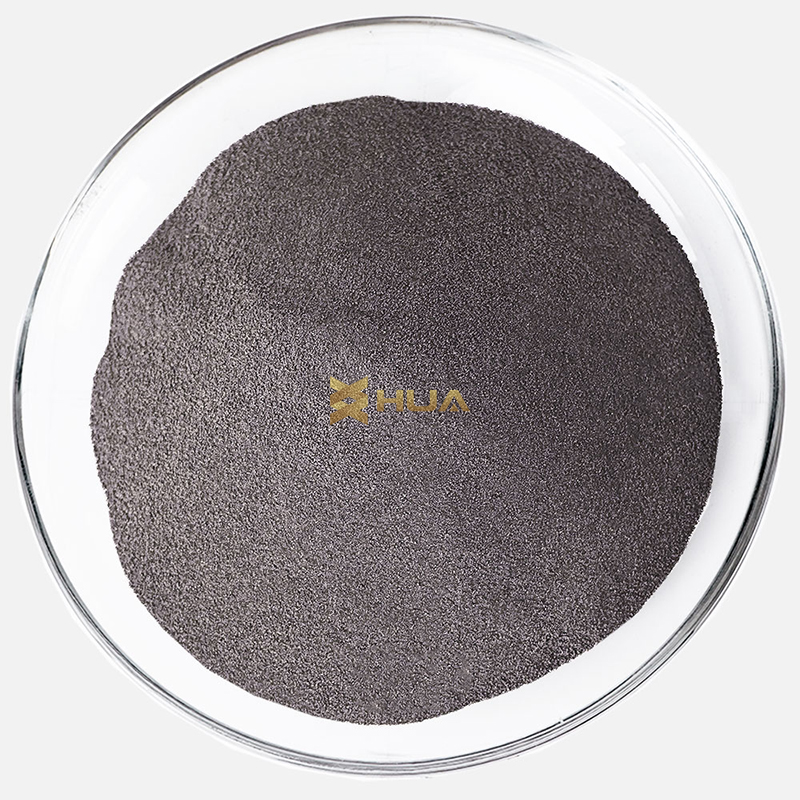

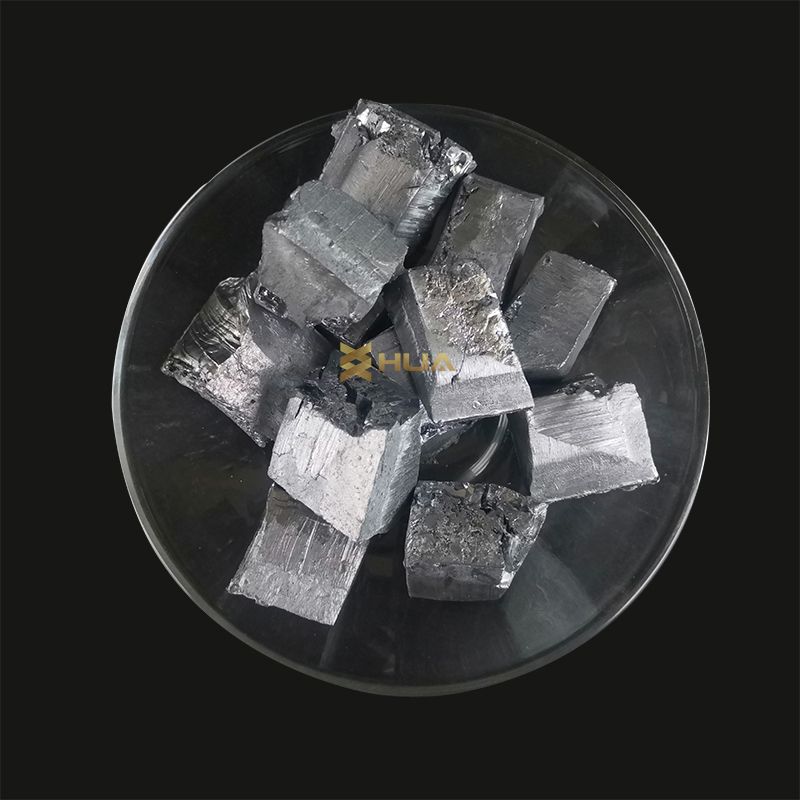

Umgubo weManganese yintsimbi engwevu ekhaphukhaphu nerhabaxa.Ukuxinana okuzalanayo 7.20.Indawo yokunyibilika (1244 ± 3) °C.Indawo yokubilisa 1962℃.Kwishishini lentsimbi kunye nentsimbi, isetyenziselwa kakhulu i-desulfurization kunye ne-deoxidation yensimbi;ikwasetyenziswa njengesongezelelo se-alloy ukuphucula amandla, ukuqina, umda we-elastic, ukumelana nokugqoka kunye nokumelana nokubola kwentsimbi;kwintsimbi ye-alloy ephezulu, iphinda isetyenziswe njenge-Austenitic compound element, esetyenziselwa ukusulungekisa insimbi engenasici, i-alloy iron ekhethekileyo, i-electrode yensimbi engenasici, njl. uhlalutyo kunye nophando lwezenzululwazi.

Inkcazo

| Into | HR-Mn-P | HR-Mn-F |

| Ubume: | umgubo | i-flake / iitshiphusi |

| Mn | >99.7 | >99.9 |

| C | 0.01 | 0.02 |

| S | 0.03 | 0.02 |

| P | 0.001 | 0.002 |

| Si | 0.002 | 0.004 |

| Se | 0.0003 | 0.006 |

| Fe | 0.006 | 0.01 |

| Ubungakanani | 40-325mesh | I-flake / iitshiphusi |

| 60-325mesh | ||

| 80-325mesh | ||

| 100-325mesh |

| Ukwakhiwa komgubo weManganese | |||||||

| IBanga | Ukwakhiwa kweMichiza% | ||||||

| Mn | C | S | P | Si | Fe | Se | |

| > | Ngaphantsi ko |

|

|

|

|

| |

| HR-MnA | 99.95 | 0.01 | 0.03 | 0.001 | 0.002 | 0.006 | 0.0003 |

| HR-MnB | 99.9 | 0.02 | 0.04 | 0.002 | 0.004 | 0.01 | 0.001 |

| HR-MnC | 99.88 | 0.02 | 0.02 | 0.002 | 0.004 | 0.01 | 0.06 |

| HR-MnD | 99.8 | 0.03 | 0.04 | 0.002 | 0.01 | 0.03 | 0.08 |

Isicelo

• iziqalelo zengxubevange ezongezelelweyo

• izinto ezityiwayo ze-welding

• i-alloy eqinile

• i-alloy yeqondo lokushisa eliphezulu, njl.

Inkqubo yokulawula umgangatho

I-1.Huarui inenkqubo engqongqo yokulawula umgangatho.Sivavanya iimveliso zethu kuqala emva kokuba sigqibe imveliso yethu, kwaye siphinda sivavanye phambi kokuhanjiswa kwazo zonke, kunye nesampulu.Kwaye ukuba ufuna, singathanda ukwamkela umntu wesithathu ukuba avavanye.Ewe ukuba uyathanda, singakunika isampuli ukuba uvavanye.

I-2.Umgangatho wemveliso yethu uqinisekiswa yiSichuan Metallurgical Institute kunye neGuangzhou Institute of Metal Research.Intsebenziswano yexesha elide kunye nabo inokonga ixesha elininzi lovavanyo kubathengi.