Ukwenziwa koMveliso oloNgezelelweyo ngumgubo weNtsimbi engagqwali 316l Umgubo woShicilelo lwe-3d

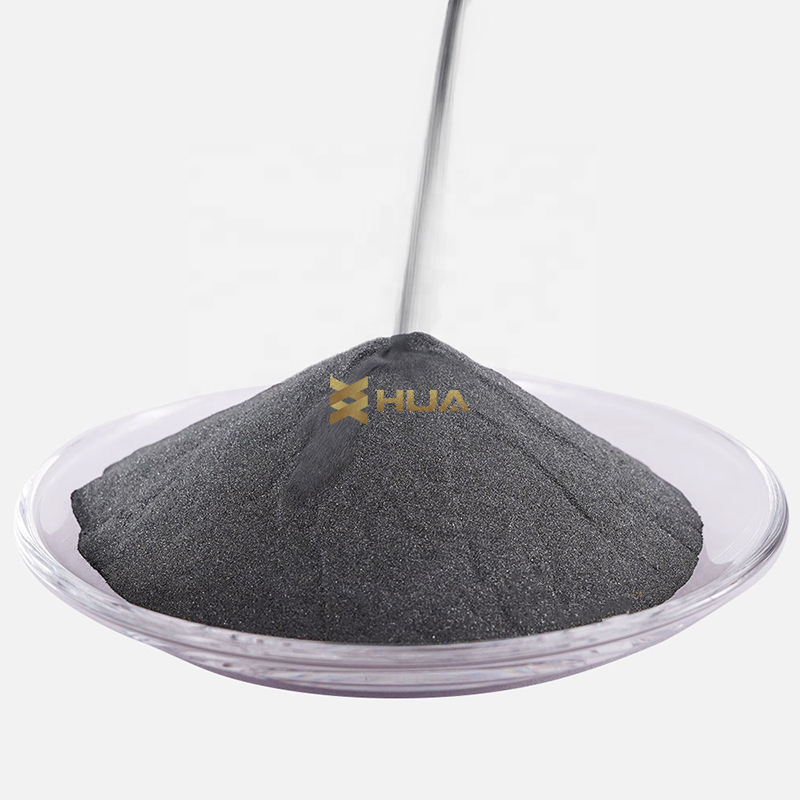

Ingcaciso yeMveliso

I-powder yensimbi engenastainless yenziwa yinkqubo ye-atomization yamanzi kwaye inokumelana ne-corrosion efanelekileyo kunye nokuqina.I-powder yensimbi engenasici inoluhlu olubanzi lokusetyenziswa kwamashishini.

Ukubonelela ngeentlobo ezahlukeneyo zensimbi engenasici kunye nobukhulu bamasuntswana ahlukeneyo.

Ngokusetyenziswa

1.Hot Isostatic Pressing

2.Metal Isitofu Molding

3.3D ushicilelo

4.Ukutshiza okushushu

Ngokwenkqubo yemveliso

1.Atomization yamanzi

2.Irhasi yamanzi edityanisiweyo kwi-atomization

3.Igesi atomization

4.Vacuum atomization

Iinkcukacha zokucaciswa

| Ukwakheka komgubo wentsimbi % | |||||||||

| IBanga | Cr | Ni | Mo | Nb | Cu | S | P | C | Si |

| 303 | 17-19 | 8-13 |

|

|

| 0.15-0.3 | ≤0.2 | ≤0.15 | ≤1 |

| 304 | 18-20 | 8-12 |

|

|

| ≤0.03 | ≤0.04 | ≤0.08 | ≤1 |

| 316 | 16-18 | 10-14 | 2-3 |

|

| ≤0.03 | ≤0.04 | ≤0.08 | ≤1 |

| 303L | 17-19 | 8-13 |

|

|

| 0.15-0.3 | ≤0.2 | ≤0.03 | ≤1 |

| 304L | 18-20 | 8-12 |

|

|

| ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 316L | 16-18 | 10-14 |

|

|

| ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 317L | 18-21 | 12-16 | 3-4 |

|

| ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 314 | 24-27 | 18-21 |

|

|

| ≤0.03 | ≤0.04 | ≤0.2 | 1.5/2.5 |

| 310 | 24-26 | 19-22 |

|

|

| ≤0.03 | ≤0.04 | ≤0.08 | ≤1 |

| 303LSC | 17-19 | 8-13 |

|

| 2 | 0.15-0.3 | ≤0.2 | ≤0.03 | ≤1 |

| 304LSC | 17-19 | 8-13 |

|

| 2 | ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 316LSC | 16-19 | 10-14 | 2-3 |

| 2 | ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 410L | 11.5-13.5 |

|

|

|

| ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 430L | 16-18 |

|

|

|

| ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 434L | 16-18 |

| 0.75-1.25 |

|

| ≤0.03 | ≤0.04 | ≤0.08 | ≤1 |

| 434LNB | 16-18 |

| 0.75-1.25 | 0.4-0.6 |

| ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 410 | 11.5-13.5 |

|

|

|

| ≤0.03 | ≤0.04 | ≤0.25 | ≤1 |

| 420 | 12-14 |

|

|

|

| ≤0.03 | ≤0.04 | 0.25/0.35 | ≤1 |

| 430 | 16-18 |

|

|

|

| ≤0.03 | ≤0.04 | ≤0.08 | ≤1 |

| 434 | 16-18 |

| 0.75-1.25 |

|

| ≤0.03 | ≤0.04 | ≤0.08 | ≤1 |

| 440 | 16-18 |

|

|

|

| ≤0.03 | ≤0.04 | 0.9/1.2 | ≤1 |

| 17-4PH | 15-17.5 | 3-5 |

| 0.15-0.456 | 3-5 | ≤0.03 | ≤0.04 | ≤0.07 | ≤1 |

| 15-5PH | 14-15.5 | 3.5-5.5 |

|

| 2.5-4.5 | ≤0.03 | ≤0.04 | <=0.07 | ≤1 |

Isicelo

Umgubo wentsimbi engatyiwa ungasetyenziselwa ukutshiza nge-thermal, i-metallurgy yomgubo, i-powder metallurgy press sintering (PM), i-injection molding (MIM) sintering filter, njl.<4000PPM, igesi atomization<1000PPM.

I-Advantage ye-HUARUI yomgubo wentsimbi

● Nokwakheka komgubo, ukungcola okuncinci

●Umgangatho ophezulu

● Umthamo weoksijini encinci

●Ukuhamba kakuhle

● Uxinaniso oluphezulu, uxinaniso lwempompo ephezulu

●Umgubo omncinci ongenanto, umgubo omncinci wesathelayithi

Inkqubo yokulawula umgangatho

I-1.Huarui inenkqubo engqongqo yokulawula umgangatho.Sivavanya iimveliso zethu kuqala emva kokuba sigqibe imveliso yethu, kwaye siphinda sivavanye phambi kokuhanjiswa kwazo zonke, kunye nesampulu.Kwaye ukuba ufuna, singathanda ukwamkela umntu wesithathu ukuba avavanye.Ewe ukuba uyathanda, singakunika isampuli ukuba uvavanye.

I-2.Umgangatho wemveliso yethu uqinisekiswa yiSichuan Metallurgical Institute kunye neGuangzhou Institute of Metal Research.Intsebenziswano yexesha elide kunye nabo inokonga ixesha elininzi lovavanyo kubathengi.